Mantén el flujo: Tu guía esencial para Mantenimiento de la bomba lobular

En el bullicioso corazón de innumerables industrias, desde la alimentaria y de bebidas hasta la farmacéutica y la química… bombas lobulares Son los héroes anónimos y confiables. Manejan fluidos sensibles, viscosos e incluso abrasivos con delicadeza y un flujo constante. Pero, como cualquier equipo que trabaja arduamente, su durabilidad y rendimiento dependen de un factor crítico: el mantenimiento preventivo.

Descuidar la bomba lobular no solo conduce a una avería repentina; puede provocar una disminución lenta y costosa de la eficiencia, la calidad del producto y sus ganancias.

¿La buena noticia? Un mantenimiento rutinario y disciplinado es sencillo. Considérelo no como un gasto, sino como una inversión en una producción ininterrumpida. Aquí tiene una guía práctica para que su bomba lobular funcione sin problemas durante muchos años.

La regla de oro: Más vale prevenir que curar

El programa de mantenimiento de una bomba lobular se puede dividir en tres categorías simples: diario, periódico y según sea necesario.

1. Comprobaciones diarias y operativas (Responsabilidad del operador)

- Estas son las comprobaciones rápidas, visuales y sensoriales que deberían convertirse en algo natural.

- El ritual de puesta en marcha: Antes de encender la bomba, asegúrese siempre de que gira libremente con la mano. Una bomba que gira con dificultad puede estar averiada, probablemente debido a lóbulos atascados o a la presencia de un objeto extraño.

- Preste mucha atención: Durante los primeros minutos de funcionamiento, esté atento a ruidos inusuales. Golpeteos, chirridos o vibraciones excesivas son claros indicios de que algo falla en el interior.

- Inspeccione el sello: Revise el sello mecánico o el empaque del prensaestopas para detectar cualquier fuga. Un pequeño goteo del empaque puede ser normal para la refrigeración, pero un flujo constante es una señal de alerta.

- Comprueba la temperatura: Los rodamientos y la carcasa de la bomba deben estar tibios, no calientes. Si no puedes mantener la mano sobre ellos, se están sobrecalentando.

2. Mantenimiento periódico (Revisión planificada)

Este es el trabajo programado y exhaustivo que previene fallas inesperadas.

A. El sello mecánico

- Lavado del sello: Si su bomba utiliza un sistema de lavado para el sello mecánico, asegúrese de que la línea de lavado esté despejada y que el fluido fluya a la presión correcta. Una línea de lavado obstruida destruirá el sello en minutos.

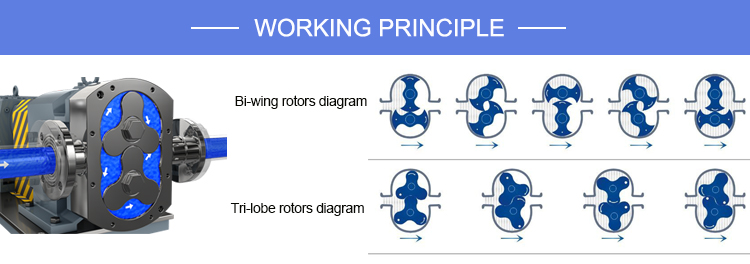

B. Los rotores (El corazón de la bomba)

Los rotores son los componentes esenciales de su bomba lobular. Su holgura es crítica.

- Inspección de desgaste: Durante los periodos de inactividad programados, inspeccione los lóbulos para detectar signos de desgaste, rayaduras o corrosión. Incluso un desgaste mínimo puede reducir significativamente la capacidad de flujo y la presión.

- La holgura es fundamental: La separación precisa entre los lóbulos y entre estos y la carcasa permite que la bomba funcione sin contacto metal con metal. Ajustar la sincronización y estas holguras durante el reensamblaje es una tarea que requiere habilidad; no escatime esfuerzos.

C. La caja de cambios

En las bombas con caja de cambios integrada, compruebe el nivel y la claridad del aceite. Un aceite turbio o lechoso indica contaminación por agua, mientras que las partículas metálicas señalan desgaste interno.

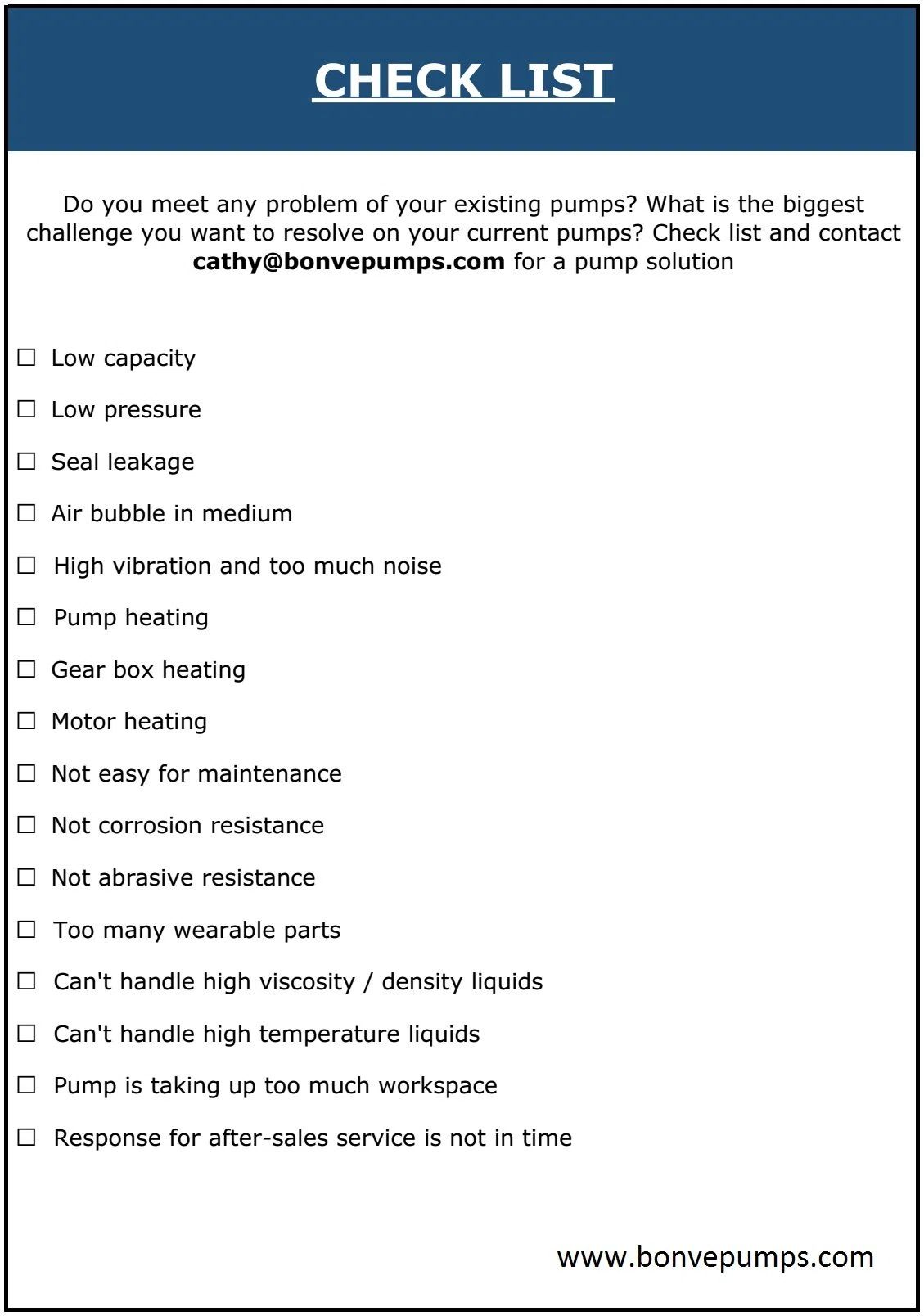

3. Solución de problemas comunes

- Caudal reducido: La causa más común son los rotores o la carcasa desgastados, lo que provoca un mayor deslizamiento interno. También podría deberse a una obstrucción en la línea de succión o a un sello del eje desgastado que permite la entrada de aire.

- La bomba no se cebará o no tiene presión: Compruebe si hay fugas de aire en el lado de succión, un sello mecánico desgastado o filtros de entrada obstruidos.

- Ruido o vibración excesivos: Esto suele indicar cavitación (comprobar el NPSH disponible frente al requerido), cojinetes dañados o daños en los lóbulos causados por objetos extraños.

- Contaminación del producto: Las juntas desgastadas suelen ser la causa. Las juntas dobles con un fluido de barrera compatible pueden proporcionar una capa adicional de protección para aplicaciones sensibles.

Su mentalidad de mantenimiento: Colabore con su bomba.

El mantenimiento de una bomba lobular no se trata solo de seguir una lista de verificación. Se trata de comprender su función en su proceso.

- Conozca su fluido: ¿Es abrasivo? ¿Corrosivo? ¿Se solidifica al estancarse? Las propiedades del fluido determinan los intervalos de mantenimiento. Una bomba que mueve lodo abrasivo requerirá inspecciones del rotor mucho más frecuentes que una que bombea aceite de cocina.

- Gestiona tus repuestos de forma inteligente: No esperes a que se produzca una avería para pedir piezas. Basándote en tu historial de mantenimiento, mantén a mano repuestos críticos: un juego de lóbulos, un sello mecánico y juntas pueden marcar la diferencia entre una parada de 2 horas y una de 2 semanas.

- Documenta todo: Lleva un registro de cada bomba. Anota las horas de funcionamiento, las tareas de mantenimiento y cualquier anomalía. Este registro será fundamental para diagnosticar problemas recurrentes y optimizar tu programa de mantenimiento.

En resumen

Una bomba lobular en buen estado es un modelo de eficiencia y fiabilidad. Al integrar estas sencillas comprobaciones diarias, seguir un programa periódico riguroso y comprender las señales de fallo más comunes, se consigue un rendimiento óptimo y predecible para el funcionamiento del equipo.

No esperes a que la bomba se detenga y haga silencio. Escúchala mientras funciona. Tu proactividad hoy garantiza un mañana sin contratiempos.