¿Cómo se producen las presiones de entrada y salida de la bomba de lóbulos rotativos?

Las presiones de entrada y salida de una bomba lobular rotativa se generan mediante los cambios volumétricos cíclicos de sus cámaras de trabajo selladas y el desplazamiento positivo del fluido por los lóbulos engranados. A continuación, se detalla el mecanismo:

1. Estructura central: la base de la generación de presión

A bomba lobular rotativa consta de:

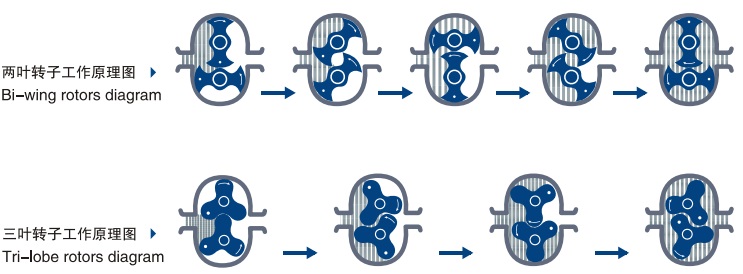

· Dos lóbulos contrarrotativos (rotores en forma de leva) con engrane preciso.

· Una carcasa de bomba estacionaria que forma un sello hermético con los lóbulos, creando múltiples "cámaras de trabajo" cerradas entre los lóbulos y la carcasa.

Estas cámaras de trabajo son fundamentales: su volumen se expande y se contrae a medida que los lóbulos giran, lo que impulsa el movimiento del fluido y los cambios de presión.

2. Presión de entrada: Presión negativa por expansión de volumen

En la entrada (lado de succión), se genera presión por la expansión de las cámaras de trabajo, lo que crea una zona de baja presión para atraer el fluido:

1. A medida que los lóbulos giran, se separan en la región de entrada, lo que hace que el volumen de las cámaras de trabajo en esta área aumente rápidamente.

2. Según el principio de desplazamiento volumétrico, el volumen en expansión reduce la presión dentro de las cámaras (por debajo de la presión atmosférica o la presión del sistema aguas arriba).

3. Esta presión negativa (succión) supera la resistencia en la tubería de entrada, arrastrando el fluido hacia las cámaras hasta que están completamente llenas (cuando los lóbulos están separados al máximo).

Nota clave: La presión de entrada suele ser ligeramente inferior a la atmosférica. Su magnitud depende de la resistencia de la línea de entrada (p. ej., longitud de la tubería, curvas, viscosidad del fluido); una mayor resistencia requiere una presión negativa más fuerte para extraer el fluido eficazmente.

3. Presión de salida: Presión positiva por contracción del volumen

En la salida (lado de descarga), se genera presión por la contracción de las cámaras de trabajo, lo que obliga al fluido a salir bajo presión:

1. A medida que los lóbulos siguen girando, las cámaras de trabajo llenas se desplazan hacia la salida. Aquí, los lóbulos se reengranan, provocando una drástica disminución del volumen de la cámara.

2. Dado que los fluidos son casi incompresibles, la reducción del volumen comprime el fluido atrapado, aumentando la presión dentro de las cámaras.

3. Cuando los lóbulos se acoplan completamente, las cámaras de trabajo colapsan por completo, forzando al fluido presurizado a salir de la salida hacia la tubería de descarga, creando presión de salida.

Nota clave: La presión de salida se determina principalmente por la resistencia del sistema aguas abajo (p. ej., fricción de la tubería, elevación, contrapresión del equipo). Una mayor resistencia aguas abajo requiere mayor presión para impulsar el fluido, y la bomba mantiene esta presión reduciendo continuamente el volumen de la cámara.

4. Mantenimiento de la presión: Sellado y funcionamiento continuo

Las presiones de entrada y salida estables dependen de dos factores críticos:

Sellado hermético: Una holgura mínima (normalmente de 0,1 a 0,5 mm) entre los lóbulos y la carcasa, así como entre los propios lóbulos, evita las fugas de fluido. Las fugas (p. ej., fluido a alta presión desde la salida que regresa a la entrada) reducirían las diferencias de presión y la eficiencia.

· Rotación continua: La rotación constante de los lóbulos asegura ciclos superpuestos de expansión de la cámara (succión) y contracción (descarga), proporcionando un flujo constante y manteniendo niveles de presión consistentes (minimizando la pulsación).

Resumen

Las presiones en una bomba lobular rotativa surgen de los cambios volumétricos dinámicos de sus cámaras de trabajo:

· La presión de entrada es una presión negativa (succión) creada por la expansión de las cámaras, que atraen el fluido.

· La presión de salida es una presión positiva generada por la contracción de las cámaras, lo que fuerza la salida del fluido.

· Ambas presiones se equilibran con la resistencia del sistema (resistencia de entrada para succión, carga aguas abajo para descarga) y se mantienen mediante un sellado hermético y una rotación continua.

Este mecanismo hace que las bombas de lóbulos rotativos sean ideales para fluidos de alta viscosidad, sensibles al cizallamiento o cargados de sólidos, ya que dependen del desplazamiento positivo en lugar de la fuerza centrífuga.